The Hydrogen Tanks Market was valued at USD 800 million in 2022 and is estimated to reach a value of USD 4,120 million by 2033 with a CAGR of 22.7%.

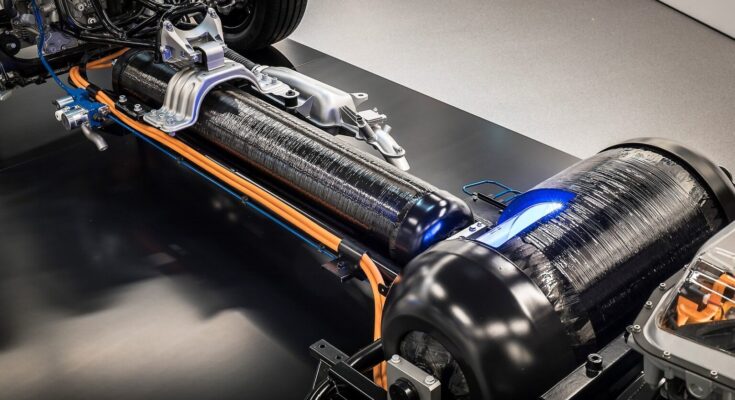

Hydrogen Tanks Market utilised as a safe and effective energy carrier is stored and transported using hydrogen tanks, which are specially designed for this purpose. These tanks are made to resist the high pressures needed to store hydrogen, ensuring that the gas will be contained and released under control when necessary. To provide the tanks the required strength and durability, materials such as metals (such as steel, aluminium) or composite materials (such as carbon fibres, glass fibres) are used in their construction. Manufacturers, suppliers, distributors, and other parties involved in the production and supply chain of hydrogen storage tanks are all included in the hydrogen tanks market. Technology breakthroughs in tank design, government initiatives to promote hydrogen as a clean energy source, rising demand for hydrogen fuel cell vehicles, and the development of hydrogen infrastructure are some of the factors that have an impact on this industry.

Increasing Demand for Hydrogen Infrastructure: The growing adoption of hydrogen as a clean energy carrier has led to an increased demand for hydrogen infrastructure, including hydrogen storage tanks. As the deployment of hydrogen refueling stations and hydrogen production facilities expands, there is a corresponding need for reliable and efficient hydrogen storage solutions.

Hydrogen Tank Standardization: Standardization efforts are underway to ensure compatibility and safety across hydrogen infrastructure. Organizations and regulatory bodies are working on establishing standards for hydrogen tanks, including design, manufacturing, testing, and certification processes. Standardization promotes interoperability, facilitates market growth, and enhances consumer confidence.

Integration of Composite Materials: Composite materials, such as carbon fibers and polymers, are increasingly being used in the construction of hydrogen tanks. These materials offer advantages such as high strength-to-weight ratio, corrosion resistance, and improved hydrogen permeation properties. The integration of composites allows for lighter and more efficient tank designs, contributing to the overall weight reduction of hydrogen vehicles and improving energy efficiency.

Key Companies

• Hexagon Purus

• Worthington Industries

• Linde plc

• Luxfer Holdings PLC

• CIMC ENRIC

• Praxair Technology, Inc.

• McPhy Energy

• HBank Technologies Inc.

• VRV S.p.A.

• Metal Mate Co., Ltd.

Segments

By Tank Type

• Type 1

• Type 2

• Type 3

• Type 4

By Material

• Metals

• Composite

By End Use

• Automotive and Transportation

• Industrial

• Chemicals

• Medical and Pharmaceuticals

• Others

By Size

• Below 100 litres

• Between 100 and 1000 litres

• Above 1000 litres

Growing Adoption in Automotive Sector: The automotive industry is a key driver of hydrogen tank demand. As the interest in hydrogen fuel cell electric vehicles (FCEVs) grows, there is an increasing need for hydrogen storage tanks that can meet automotive safety standards, provide sufficient range, and enable fast refueling. Tank manufacturers are focusing on developing tanks that can withstand high-pressure conditions and meet the requirements of automotive OEMs.

Expansion of Hydrogen Energy Storage: Hydrogen is gaining attention as a means of energy storage, especially for renewable energy integration and grid balancing. This trend drives the demand for large-scale hydrogen storage solutions, including tanks capable of storing significant volumes of hydrogen for extended periods. The development of cost-effective and efficient hydrogen tanks is crucial to enable the widespread adoption of hydrogen energy storage systems.

Government Support and Policies: Government initiatives and policies promoting the use of hydrogen as a clean energy source play a significant role in shaping the hydrogen tanks market. Supportive regulations, subsidies, and incentives can drive investments in hydrogen infrastructure, including the production and deployment of hydrogen tanks.

These key trends indicate the dynamic nature of the hydrogen tanks market as it aligns with the broader developments in the hydrogen industry. Manufacturers and stakeholders in the market need to stay updated with these trends to seize opportunities, address challenges, and contribute to the advancement of hydrogen storage technologies.

Advancements in Tank Technology: The hydrogen tanks market is witnessing continuous advancements in tank technology to improve safety, efficiency, and performance. Manufacturers are developing innovative tank designs, utilizing lightweight materials, enhancing insulation properties, and optimizing tank geometries to increase storage capacity and reduce weight.

Frequently Asked Questions

• What is the market size and growth projections?

• What is the market size and growth projection for each of the market segments and sub-segments across Countries & Regions?

• What are the top performing segments, and countries / regions of each of the markets?

• What is the market size and growth rate across key countries / regions?

• How big is the global & regional market in terms of revenue and volume?

• How far market will grow in forecast period in terms of revenue and volume?

• What factors will influence demand and supply trends across each markets during the forecast period?

• What are the technology trends shaping various markets?

• Which country / region has more opportunities?